LM-100

743(W) x 464(D) x 455(H) mm / 61 kg

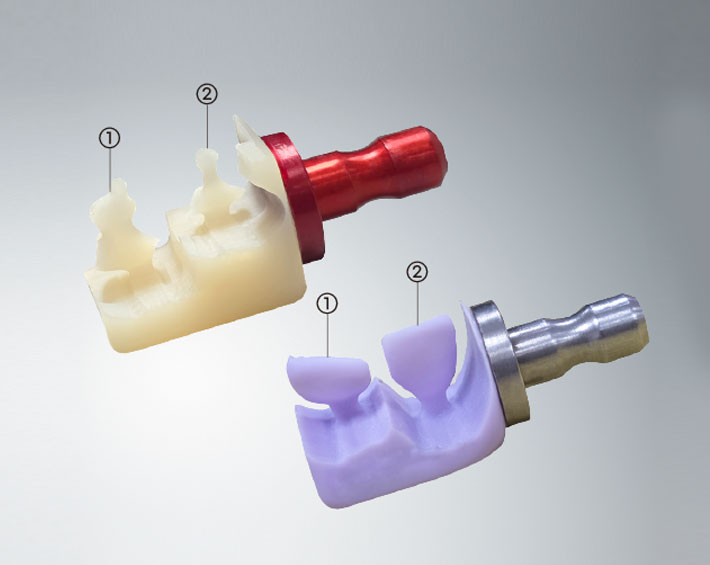

Wet Processing, Milling & Grinding Method Support

(Depends on the Material)

Dual 3 Axis

4 Motors, Dual Spindles, 50,000 rpm

8~15 min (@Grinding)

±25 um

Lithium Disilicate, Glass / Hybrid Ceramic, Zirconia, PMMA

Crown, Inlay, Onlay, Veneer, Bridge

Up to 40 mm

7" LCD Touch Screen / Built in Water Tank

100-120V AC 3A / 200-240V AC 1.5A, 50/60Hz

* Specifications and designs are subject to change without notice.